WE HAVE MOVED

Our new address is; OLRIG, BALLATER ROAD, ABOYNE, ABERDEENSHIRE AB34 5HY

Tel; 44 1224 791001

Mob; 44 7809 898 878

Enquiries (All Oceans & AC-CESS); brian.abel@alloceans.co.uk

AC-CESS ALL OCEANS

The development of the MAC-ROV and the range of options to deploy it from the surface, as a Fly-Out system, or as part of a SHUTTLE system in any depth configuration to 6000m has led ALL OCEANS Engineering to rationalise the AC-CESS Co UK Limited side of their business.

The MAC-ROV needs to be in the ALL OCEANS “stable” given that it is offered with their developed specialisation in the design and manufacture of Launch and Recovery Systems (LARS) and Tether Management Systems (TMS), it then makes sense to have the AC-ROV product in the same stable.

AC-CESS was put in place to “brand” and sell the now well established AC-ROV Hand Carry underwater inspection system and options. The brand is to be retained but all business will now be transferred to ALL OCEANS Engineering Ltd. at the same address. The AC-ROV product will continue to have its own identity; postal address, email address and contact telephone numbers.

All of the AC-CESS products were designed by ALL OCEANS Engineering Ltd and they are manufactured by them. They also employ everyone at the Aberdeen address which means that the service, support and even the staff that our customers are familiar with, will be unchanged and unaffected.

If you have AC-CESS Co UK Ltd registered on your supplier database and accounting systems then we would ask that you simply change this to All Oceans Engineering Ltd or delete it if All Oceans are also on your system. We accept that this may cause some inconvenience so apologise in advance and thank you for your understanding.

NOTE; The AC-CESS website will continue to represent the AC-ROV products and options. www.ac-cess.com

Brian Abel

Managing Director

1st April 2017

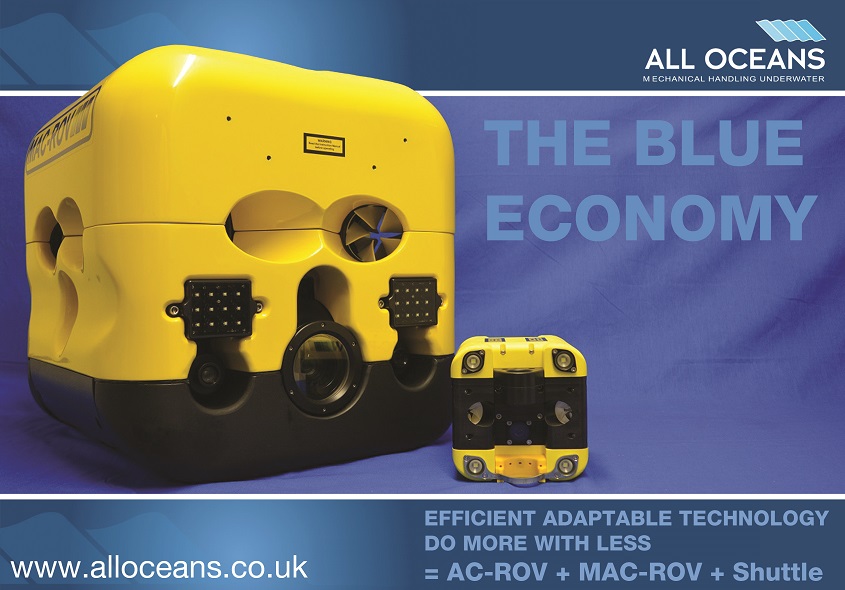

The MAC-ROV and the BLUE ECONOMY

Access all oceans with MAC-ROV systems. A ground breaking BLUE ECONOMY approach to underwater visualisation, discovery, work and recovery. The BLUE ECONOMY is about developing more efficient and adaptable solutions that do more with less. The AC-ROV, MAC-ROV and SHUTTLE systems have been developed to do just that in all wet environments to 6000m.

The essential "access" functions are simply; Deploy, Locate, Observe, Sample and Recover. This identifies the ability to “Observe” as a stand-alone function. Given that ALL OCEANS Engineering have all the skills and experience to develop complete ocean access systems (ROV, LARS, TMS) the challenge then becomes how to do more with less. IE; less capital cost and less operating cost. Smaller systems can fit on smaller vessels.

The MAC-ROV is a 4k and HD camera platform. A 500mm (20”) cube shape with six degrees of freedom. Primarily developed as the next bench mark Fly-Out system when packaged with its 250m excursion TMS but also vailable as a surface deplyed system.

The SHUTTLE is a flexible payload and mission driven deployment and recovery system allowing more to be done per dive. A MAC-ROV and TMS (standard Fly-out configuration) would automatically get SHUTTLE space. The "Shuttle" concept can be applied to any size or payload however the one illustrated here is rated for 1Te to 6000m (20,000 feet) and is 1.5m x 1.2m x 1.3m high. This is more than enough to accomodate the type of tooling that would normally require a Work Class ROV system at a fraction of the weight, power and deck space.

Some MISSION SPECIFIC SHUTTLE payload examples:

- Artefact and Sample Recovery: One MAC-ROV Fly-Out, a 7 function Schilling manipulator (Titan, Atlas or Orion), geology corer and a bathyswath.

- Cinematography: Two MAC-ROV Fly-Outs, each configured with different lights and cameras, whilst the Shuttle supports additional cameras and high density mobile flood lighting. IE; 3 independently controllable platforms separating lighting from cameras.

http://alloceans.co.uk/downloads/All_Oceans_Blue_Economy_v3.pdf

Introducing the MAC-ROV

ALL OCEANS Engineering of Aberdeen, Scotland went public in February 2016 with the fact that they were developing a new small ROV. They didn’t say how big it was, but they did qualify it as reinforcing the Company’s position at the forefront of Fly-out ROV systems and technology. They added that it would also be available as a surface deployed system. They have now released details of their new vehicle, the MAC-ROV, and a range of deployment options. Truly ground breaking and inspirational work from this committed underwater engineering business.

http://alloceans.co.uk/downloads/Introducing_the_MAC-ROV_-_D.pdf

The MAC-ROV makes ACCESS to ALL OCEANS a reality for more people and more vessels. This link is an insight into the inspiration behind it.

http://www.subseauk.com/documents/presentations/brian%20abel%20-%20all%20oceans%202016.pdf

Wireless Control LARS

ALL OCEANS Engineering Ltd of Aberdeen, Scotland continue to develop Launch and Recovery Systems (LARS) for underwater Remote Operated vehicles (ROVs) by offering more options and greater depth capability than previously available from a single source global supplier.

With many decades of detailed design experience associated with handling equipment into and out of the water, Brian Abel, who founded All Oceans in 1985, is always pushing himself and his team to deliver the best in LARS solutions regardless of depth rating, application or configuration.

Get in touch for a link to watch the latest single lift LARS handling a model 550 TMS which provides 600m excursion on a 20mm diameter tether. This is a 1500m x 3.5Te (in air payload) system for a Norwegian built electric work class ROV and wireless controlled.

All Oceans have a developed range single lift, road transportable LARS packages inclusive of the ROV and TMS as transit payload allowing quick and simple mobilisations. These simple, compact, self erecting systems are delivering big & small work class ROVs to depths of up to 6000m around the world.

AC-CESS ALL OCEANS

Ocean Access limitations are disappearing fast, and the opportunities are increasing equally as fast, so the world is set for continuing, and accelerating underwater exploration, discovery and development. ROVs are a fundamental access tool, but what type and size is best suited to first step exploration and discovery ? How small can a capable, all depth, ROV access system be ?

These are questions recently put to an Audience at Subsea Expo 2016 in Aberdeen. You may think there are technical limitations, but in reality there aren’t – NOT anymore. Yes, some things are tricky, but as Engineers, Operators and Researchers, we have made it to full ocean depth, so the stage is now set to refine and evolve underwater access solutions, of all types and for all depths, and who knows what applications. The “disappearing limitations” are actually political, and centered on The Law of the Seas. These Laws are well advanced and evolving under the UN mandate that OUR OCEANS, and their resources, should belong to the whole of mankind.

So are All Oceans developing a new ROV ? Well yes, and it is going to be bigger than the AC-ROV, but we are not going to say by how much, at least not yet.

Given All Oceans' lead in the Fly-out and micro ROV market with the AC-ROV 3000 and AC-ROV 100, then the inevitable question of "does it come as a complete system" will be asked. So yes again, the solution will satisfy both deployment methods; surface deployed system and Fly-out.

Going back to its size, it will not be big enough to carry significant sampling tools, but this is not a compromise on what defines an access capable system; DEPLOY - LOCATE - OBSERVE - SAMPLE - RECOVER.

If you have an ROV and a TMS, then together they make up the submersible package. To harness all of the advantages of having a small deep capable ROV system, the solution spreads the functionality across these two elements to best advantage. Instead of a TMS, there is a SHUTTLE, and as its name suggests it provides flexible payload capacity. A principle package will be the new Fly-out ROV and TMS, whilst others will be mission specific; sampling, scientific, or whatever. A complete vessel deployed 6000m system, with 2 man control station and work area, will load out at under 5Te, have a footprint of 6m x 2.5m and have a peak power demand of 20kw.

The "Small Advantage" or in other words the benfits are;

Small ROV systems don’t need big support vessels.

They are easier and less expensive to move around the world, easier to lift on and off vessels, easier to sea-fasten and to supply with power.

Going small reduces Capital Expenditure and Operational costs all round.

The project was started two years ago and is well advanced with some significant elements built, in build and being progressed through testing. Watch this space.

Electronic Design Engineer & Software Engineer

Required to further develop the production, test and servicing of our world leading mini and micro ROV systems (AC-CESS.COM). Past work or personal experience should include hands on electronic design, production, assembly, trouble shooting and servicing. Motion control software development experience is also essential. The position brings with it the potential for the right individual to develop a career in robotic systems. Applications with cv to admin@alloceans.co.uk

6000m LARS

All-Oceans Engineering Limited and Sub-Atlantic Limited, both internationally acknowledged as leading companies in the ROV industry, have facilitated a substantial order from Subsea Resources Plc for a 6000m ROV system for the survey and recovery of valuable sunken cargo and treasure.

Sub-Atlantic's 6000m innovative Comanche ROV was selected as it perfectly met the requirements designated by Subsea Resources. It then followed that All Oceans' were the preferred partner to cover all aspects of the Launch and Recovery System (LARS) deign, manufacture and vessel integration.

All Oceans are an approved supplier of all types of umbilical handling systems and LARS to Sub-Atlantic and for Sub-Atlantic submersibles, whilst, All Oceans had worked with some of Subsea Resources' key people on deep ocean studies and equipment evaluations several years ago.

All Oceans and Subsea Resources understand the many and not insignificant issues associated with launching, recovering and supporting what is not only a substantial equipment investment but also a tool fundamental tool for realising rewarding salvage operations.

The culmination of technical knowledge and expertise of All Oceans and Sub Atlantic, has resulted in this high profile successful sale. This unique business partnership is evidence that a strategic alliance of resources can result in a competitive edge within the subsea industry. It is also evidence that companies working primarily within the oil and Gas industry can successfully succeed out with traditional target markets.

Instrument Winches

With more than 20 years experience in the detailed design of Winches and Marine Handling Equipment, All Oceans Engineering Limited have developed experience in the custom design and manufacture of a variety of Instrument cable winches. All winches are designed, built and tested in house at their facility on the outskirts of Aberdeen.

OPTIONS

Electric, Hydraulic, Pneumatic or Manual Drive

Multi-core Cable, Wire Rope or Fibre Rope

Electrical, Optical, Slip Rings or Rotary Fluid Unions

"Plug and Play" (no slip ring)

Automatic or Powered Level Wind

ZERO MAINTENANCE

ALL OCEANS have more than a decade of experience in the design and manufacture of underwater winches and equipment. The marine market is now benefiting from this experience in that many winches are built in material combinations for no / low corrosion with dry / water lubricated bearings, sealed drives etc. Many solutions, like those shown, only need periodic visual inspection.

Concept ROV

Introducing the patented AC-ROV Concept Vehicle, a vision of the future?

www.ac-cess.com

See AC-CESS, the AC-ROV and ALL OCEANS at OI 2004, Excel Centre, London, 16th-19th March, STAND No. 546

A Tall Order

If not the heaviest, then certainly the tallest, design and build project undertaken by ALL OCEANS from their Aberdeen facility to date. The picture shows an "ILUC" handling system standing at its full height of 15m (50 feet)alongside the workshop.

If not the heaviest, then certainly the tallest, design and build project undertaken by ALL OCEANS from their Aberdeen facility to date. The picture shows an "ILUC" handling system standing at its full height of 15m (50 feet)alongside the workshop.

An "ILUC" is an Internal Line-Up Clamp, simply described as a torpedo shaped device that fits inside a pipe, and as its name suggests, is used to align two pipe ends prior to welding. The "Tall Order" was from the Deep Blue Project Team to design and build the handling system for various sizes of "J-Lay" line-up clamps.

The handling system had to get the ILUC into the open pipe end, however, the pipe end can be anywhere between 44m and 56m (184 feet) above the deck, and its angle to the deck could be anything between 30 and 90 degrees.

This required the development of what is called the "feeder tube". It is guided along the centre line of the pipe until it lands on the pipe end. The feeder tube stops and the clamp carries on being lowered down the pipe bore on the load rated handling umbilical.

The system is installed 60m (200 feet) off the deck. As such, one of the principal design requirements was that the solution had to be "minimum maintenance". Apparently, technicians need notice so that they can take motion sickness tablets before going up the tensioner tower, to where the system is located!

The system was assembled and tested at ALL OCEANS works prior to delivery complete with the umbilical, slip ring assembly, hydraulic drive and integrated remote control system.

FISH PEN and TANK INSPECTION SYSTEM

Do you have a test tank with equipment in it that you would like to check or inspect, but don't want to mobilise an ROV system or don't have one available? Then the following tank inspection system may be what you need.

Do you have a test tank with equipment in it that you would like to check or inspect, but don't want to mobilise an ROV system or don't have one available? Then the following tank inspection system may be what you need.

Developed and proven for handling pan and tilt camera units in salmon farm fish pens, the two-winch system is ideal for simple tank inspection work. A pan and tilt camera on its own can only be moved manually, however, using two winches they can be moved over the full width and depth of a pen or tank.

The pan and tilt camera is suspended on lines from the two winches. Operating the winches together or separately greatly increases the tank viewing options.

The problem that fish farms had was that they could only set their pan and tilt cameras a fixed depth and location within their fish pens.

Operators need to watch the fish feeding so that they can control the feed supply rate and in some cases the feed specification.

At the start of a feeding session, the fish are frantic at the surface, but as the session progresses, the fish move down and progressively more and more of them stop feeding.

The operator wants to control the feed supply rate by watching, not so much the fish, but the feed pellets to see how much is falling past the fish. Feed is expensive and the pellets are quite small, they also come in different "sink" rates.

With the winch system, the operator can follow the fish down or across the tank when a current is running. The objective is to keep feeding for as long as possible, whilst wasting as little feed as possible.

Pull-In Winches

BONUS or PENALTY?

BONUS or PENALTY?

ALL OCEANS, have been designing and manufacturing underwater winches since 1991, delivered two more custom designed units to a local customer in June 2002.

The requirement was one of those "time is of the essence" orders. Even so, ALL OCEANS accepted and delivered on time. Both systems were assembled, commissioned, tested and delivered inside 6 weeks, and yes, the paint was dry.

The programme was roughly 2 weeks design, 2 weeks manufacture, 2 weeks assemble, paint and test. Considering that no part of the winch design pre-existed, meant that there was no margin for error. In this respect, ALL OCEANS acknowledge the support of their many suppliers and workshop resources in helping to get this job out on time.

Although the "time is of the essence" term were accepted, the customer's proposed late delivery penalty was not.

At the risk of being controversial, ALL OCEANS add any penalty risk 100% to the bottom line price. Unless supply is totally controllable, such as a supply from stock, then penalties are very difficult to pass down a supply chain. So Customers, what about a Bonus option as opposed to a Penalty option?

Is there a difference between a % BONUS rather than on a % PENALTY contract?

Does one option have a different effect on attitudes and the progress of the work?

How far can a Bonus option be passed down a supply chain compared with a Penalty?

Would we feel different about a "Bonus" project even if the end price were the same as for a "Penalty" project?

For information, the two winches were rated to pull 8,000kg bottom wrap and handle up to 300m of 16mm steel wire rope. Level wind combined grooved drums and powered spooling.

Performance was maximised for the specified ROV hot-stab hydraulic supply and flow. Operating depth is in excess 3000msw.

ALL ELECTRIC in ARGENTINA

A brand new multi-purpose support vessel, the "Skandi Patagonia", is Argentina bound with a shiny new ROV system aboard. ALL OCEANS were contracted by the Norwegian ROV manufacturer ARGUS Remote Systems of Bergen to supply a TMS and Launch and Recovery System to suit their electric work class ROV.

All Oceans and Argus worked closely with the Norwegian customer to supply a fully vessel integrated system that would support the saturation diving and well work-over facilities and be a stand along ROV capability suited to the harsh environment of the South Atlantic.

The all electric and field proven TMS option that has been available from All Oceans for many years now combines well to make a very capable and compact all electric ROV package.

ARGUS complimented All Oceans on the simplicity, ease of operation, integration and service aspects of the TMS. This is the third All Oceans TMS that has been married to an Argus ROV and their experience is that they just keep on getting better.

Also part of All Oceans supply was the umbilical winch, electro-hydraulic power pack, local and remote controls for the winch and crane, and the TMS to crane load latch. All of the equipment was designed, assembled and tested in Aberdeen at All Oceans works, prior to shipment and installation on the vessel in Norway mid November.

Acceptance trials went very well. A number of hitch free trial dives were carried out to prove the various systems before the final test of rigging a lift line to the diving bell was done. This emergency intervention capability was identified early on in the project and has an importance associated with the level of diving support capability in Argentina.

In a matter of minutes, the ROV was in the water unlatched from the TMS, had located and picked up on the crane wire and hook, then located the bell and the emergency lift sling. Then, in only two attempts it had safely hooked the bell lift sling. The 10Te bell was then cross-hauled to the vessel deck all without incident.

The ease and precision with which the operation and other manoeuvres was carried out is testament to a very capable and well designed ROV system.

DEEP SUBMERGENCECAPABILITY

Southampton Oceanography Centre has commissioned the UK's first remotely operated vehicle (ROV) dedicated to deep-ocean exploration and research.

Capable of carrying out research down to depths of 6,500 metres the ROV will give scientists access to 98 per cent of the world's oceans.

Based at Southampton Oceanography Centre, the ROV will also be available for use by researchers from across the UK, as part of the marine science technology pool.

Professor Priede of the Department of Zoology, University of Aberdeen said: 'This is a long overdue development that will greatly

enhance the ability of researchers in British Universities to make direct observations, retrieve samples and carry out experiments in deep water. There are areas of the continental slope which are too steep to be surveyed by conventional towed gear and nets. They are no go areas in which we know important species of fish are likely to spawn and rear their young. The ROV will make these areas accessible for the first time.'

The Tether Management System for the project is to be supplied by ALL OCEANS Engineering Limited of Aberdeen, who are obviously delighted to be involved in such a prestigious British project.

Function testing of the TMS is scheduled to take place in Aberdeen in the last quarter of 2002. 0nce complete it will be despatched for ROV and Launch and Recovery System integration and testing. The first sea trials are understood to be scheduled for the second quarter 2003.

The SOC web site has more details and information about the Project including technical specifications of some of the hardware.www.soc.soton.ac.uk/OED/ROV/index.php

The large range of various TMS building block components that ALL OCEANS have developed over the years allowed a near proven solution to be offered to the Project.

This was a major advantage when it is appreciated that what the Project called for was a TMS not much bigger, or heavier than what would normally be used with an "Inspection" class ROV, but with a load rating appropriate to a heavy "Work" class ROV.

The winch module is one of the smaller units in the All Oceans' range and will provide 260m minimum ROV excursion on the Project supplied special tether cable.

The TMS is rated for a maximum 4000kg ROV and has a proof load rating of 12,000kg but in air will weigh less than 1000kg.